The quality of “Rustik” parquet floor has the technical characteristics of parquet flooring in “Selekt”, and in appearance it gives the impression of an unfinished floor, the knots give the effect of time and the charm of the floor that produces a suggestive impression of wear and tear over time, very interesting for creating the atmosphere of past times that provokes nostalgia

Large scale two-layer parquet is a product of high quality treatment. We manufacture it on new generation machines of the WEINIG manufacturer from Germany.

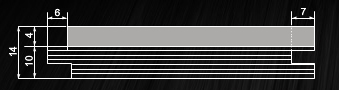

The very expression “two-layer” says that the parquet is made of two layers: the upper and lower layers. The upper layer of parquet is of the highest quality hardwood such as oak, ash, walnut, hornbeam, beech and other hardwoods. The substrate, or the lower layer of parquet, is made from birch multiplex, seven-layer plywood slab, 10 mm thick, whose layers are cross-glued which makes the plywood and therefore makes the parquet stable.

The top and bottom layers are glued using vinyl adhesives that have high moisture resistance and are sealed on purpose-oriented presses for these floors. After pressing, the parquet is left to stand in order to stabilize or condition it. After that, the finalization of the production ensues; the glued elements are calibrated and profiled to a precise measurement with a pen and groove (male and female) from all four sides. The fronts and sides of the parquet are profiled by knocking over the edges of the wear and tear layer at an angle of 45 degrees, and by joining the parquet boards, there is a pronounced joint on all four sides. Before the final oiling process or painting, the profiled parquet is finely sanded with the required granulation of sand paper on multiple ribbon wood sanders, depending on whether the final protection is oil or paint.

For the final protection of the parquet, we use the most modern technology of today, LED technology, which means that the drying of the coating of oil or lacquer on the parquet is done on the flow line with special LED lamps. Drying is provided by the oil and lacquer that have photo initiators that react to the LED light by binding it immediately i.e. drying it.

Two-layer parquet is compact, made of hard material, the birch base is also hard because it has the approximate solidness of beech and after setting the two-layer parquet does not ”effervesce” i.e. there is no occurrence of “dissipation”.

It is recommended for business and residential spaces and exclusively in terms of spaces that have floor heating.